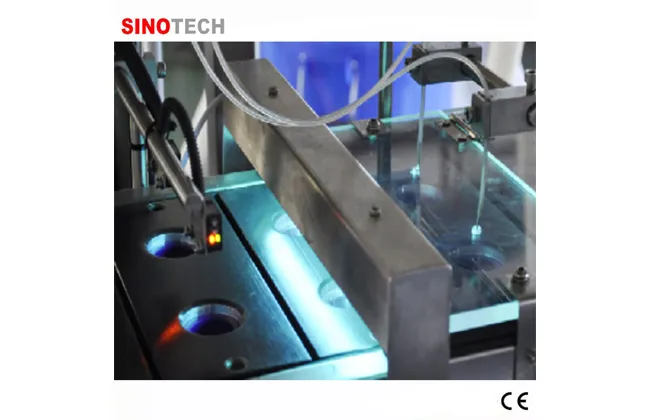

ST-KJ400 Automatic High Speed Coffee Capsule Filling and Sealing Machine

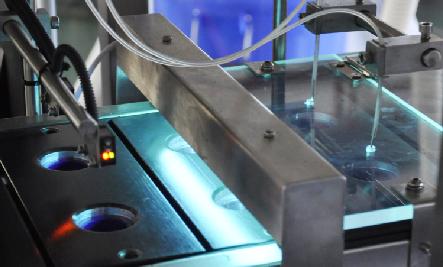

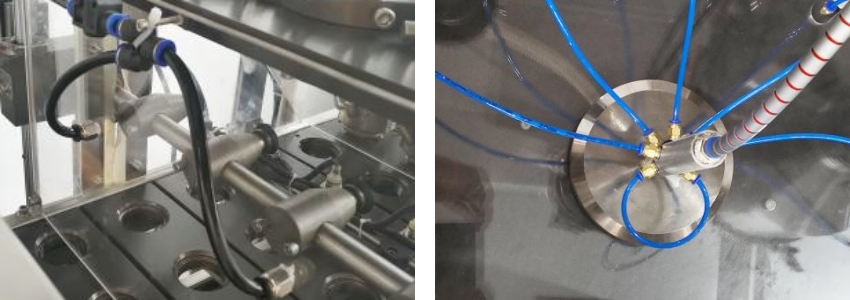

This is a fully-automatic capsule filling sealing machine. It can produce almost all compatible capsules, such as Keurig k cup, Nespresso, Dolce Gusto, Lavazza, paper cup and custom-shaped, etc. This machine is the highest speed model with highest level of quality in China now. We successful achieved machine parts mechanical linkage that gurantee the machine with long running stability and service life of the machine have obvious advantages, which reach the top design concept in Europe. Supported by our company’s sophisticated design team, this machine has the most advanced technology and leading-edge performance, with many unique patents.

English

English français

français Español

Español русский

русский português

português العربية

العربية Deutsch

Deutsch tiếng việt

tiếng việt 한국어

한국어 Türkçe

Türkçe Malay

Malay