-

Products

-

Bioreactor Fermenter

- Glass Bioreactor

- Parallel Bioreactor

- Stainless Steel Bioreactor

- Stainless Steel Fermenter

- Industrial Bioreactor Fermenter

- Enzyme Bioreactor Fermenter

- Mammalian Cell Bioreactor

- Vaccine Bioreactor

- Solid State Fermenter

- Airlift Fermenter

- Photobioreactor

- Fully Automatic CIP System (Acid and Alkali)

- Industrial Process Equipment

- Centrifuge Separator

-

Suppository Production Line

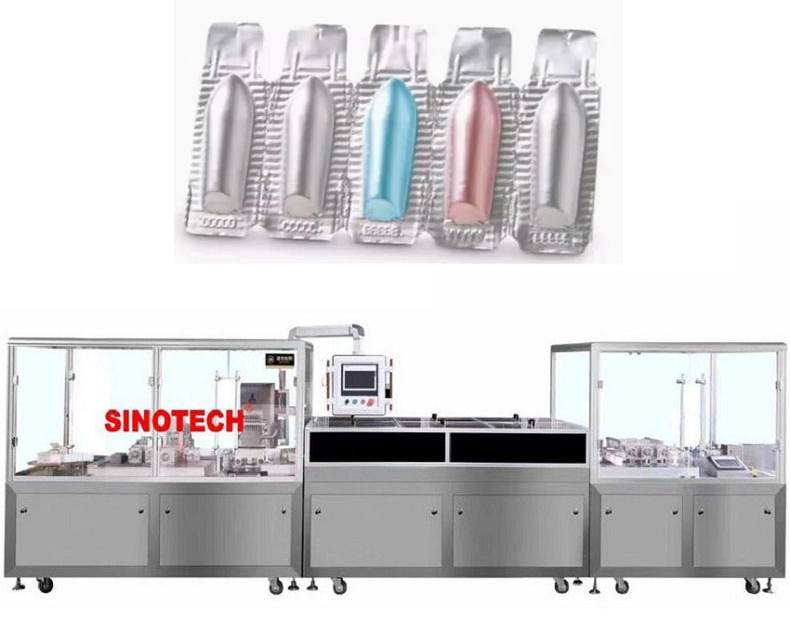

- Alu Alu suppository production line

- Full Automatic Suppository Filling and Sealing Machine with 1Filling Head

- Suppository making shell machine for sale

- Sinotech 15Model Suppository Making Machine

- Suppository filling and sealing machine with 1 filling head

- Full-automatic Suppository Production Line SJ-2L

- Suppository filling machine

- Suppository Filling And Sealing Machine

- 6 Heads Suppository Forming Machine

- 7 Filling Heads Continuously Automatic Suppository Production Line

- 3 filling heads Sinotech-SL suppository filling and sealing production line

- Lab Type Semi Suppository Filling And Sealing Machine

- SJ-1LB Lab Semi Suppository Production Line

- Soft Gel Production Line

-

Tablet Press Machine

- ZP27D Rotary Salt Tablet Press Machine

- zp15/17/19 Paint style tablet press machine

- ZPS-8/10/16 Intelligent rotary tablet press

- Zp9 Rotary Tablet Press Machine

- Zp29/31/33 Multifunction Herb Tablet High Speed Double Sided Tablet Press

- Hydraulic Tablet Press

- Medical Tablet Press Machine

- Salt Tablet Press Machine

- Candy Tablet Press Machine

- Tablet Press Punch Die TDP Mold ZP Mold

- Big Size Two Layer Double Color Dishwashing Tablet Automatic Rotary Effervescent Tablet Press Machine

- Thp Series Big Flower Basket Tablet Press Machine

- ZP-31D Rotary Tablet Press

- ZP-45D Rotary Tablet Press

- ZPW-17D Rotary Tablet Press

- ZPW-23 Three Layer Press Machine

- Single Punch Tablet Press

- ZP15D 17D 19D Rotary Tablet Press

- Chicken Essence Block Production Line

-

Capsule Filling Machine

- Njp200 Pharmaceutical Automatic Softgel Hard Capsule Filling Machine

- Njp400 Model Gel Capsule Filling Machine for Herbal Powder

- NJP600 Capsule Filling Machine

- NJP800 Automatic Capsule Filling Machine

- NJP1200 Fully Automatic Capsule Filling Machine

- Njp2500 Automatic Hard Gelatin Capsule Filler Machine

- NJP3800 Capsule Filling Machine

- Cgn-280-D Semi-Automatic Capsule Fill Machine

- NJP7500 Capsule Filling Machine

- CE Pharmaceutical Hard HPMC/Gelatin/Halal/Vegetarian/Hollow/ Pullulan/Empty/Hard/Vegetable/Clear Capsules Filling Packing Machine/Encapsulation Machine

- High Capacity Horizontal Capsule Polish Machine with Sorter

-

Packing Machine

- Small Automatic Chilli Powder Chili Pepper Seasoning Spice Salt Sugars Sachet Weighing Packaging Packing Machine

- Automatic Flour Chili Pack Bag Small Sachet Granule Milk Powder Filling Machine Powder Sachet Packing Machine

- Lab Type Semi Blister Sealing Machine For Capsule /Tablet/Softgel

- Lab Type Semi Blister Sealing Machine

- YD-420F Model Surprise Egg Blister Packing Machine

- DPH-260 Model High Speed Blister Packing Machine

- DPP-270S Blister packing machine (blister with paper card)

- DDP-140 Automatic Electric Blister Packing Machine for Tablet Pills Capsule

- Tablets Automatic Alu-pvc Blister Packing Machine

- DPP 80 Automatic Jam Honey Blister Packaging Machine with Peristaltic Pump

- DPP-80 Automatic Aluminum Plastic Blister Packing Machine Capsule Blister Packing Machine

- Full Automatic Oil Liquid Blister Packaging Honey Chocolate Sauce Cream Syrup Food Jelly Blister Packing Machine

- Fully Automatic Butter Cheese Paste Cream Blister Packing Machine

- Desktop Blister Sealing Machine

-

Tablet Counting Machine

- Automatic 16 Channel Vibration Intelligent Visual Capsule Counting Machine

- High Efficient Tablet Pharmaceutical Production Line

- Pharmaceutical Grade Tablet Pill Counting Machine

- Multi Channel Automatic Vibrating Bottle Capsule Counting Machine

- Automatic Candy Bottle Counting Machine

- Benchtop Tablets Capsules Pills Counting Machine

- YL-8 Lane Electric Automatic Softgel Capsule Tablet Counter 8 Channel Bottling Capsule Tablet Counting Machine

- Yl-2A Desktop Small Electronic Tablet Counter

- YL-2 Tablet Capsule Candy Softgel Counting Machine

- Freeze Dryer

- Spray Dryer

- Membrane Filtration Equipment

-

Filling Machine

- ST-100R Automatic High Speed Coffee Capsule Filling and Sealing Machine

- ST-KJ400 Automatic High Speed Coffee Capsule Filling and Sealing Machine

- 240 Model Oral Liquid Plastic Ampoule Filling Sealing Machine

- Oral Liquid Plastic Ampoule Filling Sealing Machine

- SINOTECH250-B Automatic Tube Filling and Sealing Machine

- SINOTECH350-B Model Automatic Plastic Tube Filling and Sealing Machine

- Fully Automatic Filling Sealing Machine for Plastic Toothpaste Tube Soft Cosmetic Cream

- Single filling head YD300A--automatic Cartridge filling machine

- 200L Hydraulic Extruder --(SINOTECH)

- Coffee Capsule Filling and Sealing Machine

- High Speed Linear Type Coffee Capsule Filling and Sealing Machine

- DJ-50D multifunctional vertical box filling machine

- SINOTECH-60S Automatic Aluminum tube filling and Sealing Machine

-

Bioreactor Fermenter

- Project

- Company

- Application

-

Services

- Blog

- Resources

- Contact

English

English français

français Español

Español русский

русский português

português العربية

العربية Deutsch

Deutsch tiếng việt

tiếng việt 한국어

한국어 Türkçe

Türkçe Malay

Malay