Machine Technical Parameters

Model | ST-100R |

Product | ground coffee |

Parts Contact With Product | Food safe Stainless Steel AISI 304 |

Capacity | 35-80capsules/minute |

Feeding | servo driven auger filling |

Filling Weight | 0-20g |

Filling Accuracy | ±0.05g |

Power | 3Phase 220/380V 50/60HZ 5KW |

Air Supply | ≥0.6Mpa |

量Air Consumption | 0.3m³/min |

Certification | CE, UL, ISO, FDA, GMP, CSA标准Compliant |

Weight | 1000Kg |

Dimension | 1590×870×1983mm |

Characteristics

1. The machine could equipped automatic vacuum hopper or screw infeeder that infeeding products automatically when the hopper is lack of products. (Optional)

2. Special storage designs that can stockpile a large number of cups per time and automatically feed the cups to the packaging line. In addition, putting the capsules is very easily, it reduces the labor cost and time for filling capsules manually. Likewise, this system completely solves the common problem of stuck capsules and damaged capsules.

3. The auger filler in this machine has world highest precision that can reach 0.05 grams, furthermore it is leak-proof, which helps seal better. The material contact machine is all SS304; it meets the medical hygiene standards. Also, the barrel can be quickly disassembled and purified. The material of the barrel is stainless steel, it has the advantages of being resistant to cleaning, break and scratching.

4.Original designed capsule rim completely cleaning system, which can achieve nearly 100% none dust on rim.

5. The lid is taken with vacuum suction. We used high quality suction cups to guarantee the stability and long usage.

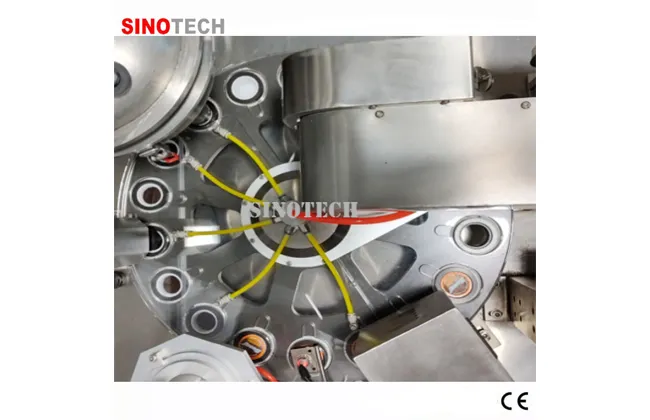

6. Servo controlled independent sealing and cutting station guarantees a tight and pretty seal. The biggest advantage of this station is the cutting lid without edge waste. That is we can cut the lid diameter from roll film exactly as the same as the cup diameter. Such stations are designed inside the machine frame, save a lot of space for customers.

7. Super nitrogen filleing system. From the beginning of the coffee to the end of the packaging, it is exposed to nitrogen gas, and keep the oxygen almost none.

8. Equipped with detecting devices. No cup no filling, no film no sealing, rejecting waste, safety door, etc.

9. Original designed automatic rectify deviation guarantees a tight and pretty seal. It can assure 100% sealing without sealing leakage or sealing insufficient.

English

English français

français Español

Español русский

русский português

português العربية

العربية Deutsch

Deutsch tiếng việt

tiếng việt 한국어

한국어 Türkçe

Türkçe Malay

Malay