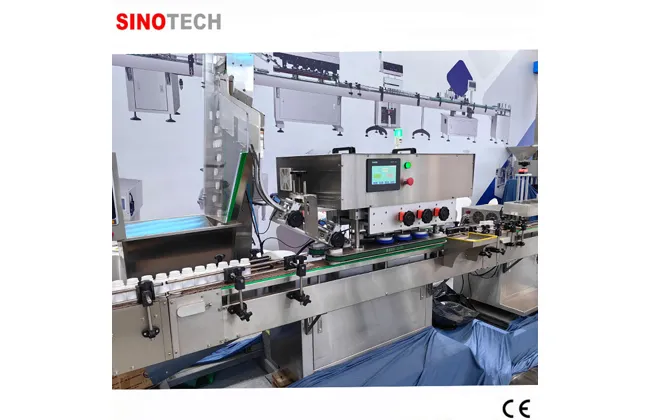

Main Features 1.Chinese and English man-machine interface, using industrial PC/PLC control. The display can display the number and name of the current product; current product standard weight; current check weight value; standard check weight, upper limit, lower limit, and dynamic average weight readings; dynamic accuracy standard deviation Gauss curve; qualified product curve /Pass rate ratio number; pass rate bar graph/number; qualified product/defective product ratio bar graph, product weighing weight distribution graph; current checkweigh belt line speed and corresponding product passing speed at this speed; curve Display the most recent 50 weight values; can set and display the acceptable upper and lower limit of the checkweighing range; counting (counting within the qualified range and out of the range respectively); can be manually adjusted to zero; and can also display the date, time, and operator ; There is a start/stop soft switch display; there is a recording and query function of check weighing data, and all alarm information is displayed. 2.It can establish different programs according to the information of different products, set the qualified weight range, correction factor, etc.; can store 100 product information parameters (for direct recall when using), and the product name has the functions of editing, saving, deleting and so on. With advanced statistical functions, histogram, dynamic distribution diagram; 3.The equipment transmission motor uses a maintenance-free, high-torque DC drive stepping motor 4.The check weighing conveyor is equipped with a windshield to reduce the influence of airflow on the check weigher 5.The device can be set to 3-6 different security access levels, 7.5-inch screen, Windows style operating system 6.The transmission direction, speed and height of the equipment can be adjusted, and the transmission belt is easy to disassemble and clean. 7.Hundreds of product switching, hundreds of thousands of data records. 8.A guardrail is installed above the conveying mechanism, which can be adjusted according to different sizes of products. 9.The checkweigher conveyor belt is composed of three parts: input section, checkweigh section and output section. 10.The input end has a standard feeding conveyor belt, and the output end has a special blown ejector 11.The height of the checkweigher detection platform can be adjusted arbitrarily within the range of 750±100mm. 12.The checkweigher unqualified product collection box is on the side of the output section of the operation surface, which is made of imported acrylic. 13.The checkweighing sensor of the equipment is the FIT/C3MR digital dynamic sensor produced in Germany. 14.The equipment can record daily test data, and the data will not be lost even if the power is suddenly cut off. 15.The automatic bottle separation/organizer installed above the input section of the equipment can effectively separate the products one by one for weighing, and there will be no bottleneck phenomenon. 16.The equipment can set the upper and lower limit of checkweighing arbitrarily, and has the function of upper and lower limit alarm elimination, weight classification selection function and continuous elimination alarm function. Continuous error is the sound and light alarm function; 17.The rejection method of unqualified products under check-weighing is reasonable in design, reliable in operation, and the rejection rate reaches 100%. 18.Can display three different weight types: overweight, normal, underweight, and display the real-time average weight. 19.Convenient adjustment of relevant parameters, which can quickly adjust the best dynamic weighing accuracy. 20.The checkweigher is equipped with dynamic and static weighing operation modes, which can be switched. 21.The checkweigher is easy to set up, and can store and call the measurement parameters of products of different specifications. 22.The checkweigher has a counting function, and it should count and display the total number of inspected products, the number of qualified products, the number of waste products and the number of rejected products. 23.The device has automatic data saving and restoration functions (restore to factory settings), and the data will not be lost when the device is powered off. 24.The operation interface has the function of upper/lower limit setting of each parameter, output count, average number, file storage, clear and reset function. 25.Display information, and have hierarchical password protection. 26.The checkweighing sensor is a manual operation correction function. 27.It can realize the functions of fully automatic operation, monitoring, detection and recording of the equipment, and can realize the function of setting and modifying the process parameters online. 28.Equipment has an automatic fault diagnosis system, with proper fault detection, diagnosis, identification, explanation and alarm functions, displays the faults that cause the equipment to stop, and displays the fault information of the equipment on the display screen. 29.The emergency stop button of the equipment is a red mushroom-shaped emergency stop button with self-locking function. The emergency stop switch is installed at the uppermost position of the operating surface, and the self-locking can be turned off in the fastest time when necessary, and all electrical and gas pipelines can be cut off. In the absence of an operator or communication line input command, the system will not restart. 30.When the control system encounters an unexpected power failure, it can be restored to the original state before production after restarting, and can operate normally. 31.This system has RS232/485-2W port to establish real-time communication with the upper computer, feedback the weighing data to the upper computer for effective control, and guarantee the highest qualified rate of the product. |  English

English français

français Español

Español русский

русский português

português العربية

العربية Deutsch

Deutsch tiếng việt

tiếng việt 한국어

한국어 Türkçe

Türkçe Malay

Malay